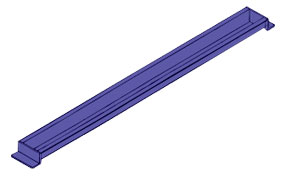

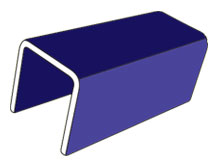

Including 100mm wide top flange eliminates the necessity for a plywood infill, so cutting down maintenance cost.

Length (m)

2.5, 1.8, 1.2

Weight (kg.)

26.4, 18.0, 11.9

Including 100mm wide top flange eliminates the necessity for a plywood infill, so cutting down maintenance cost.

Length (m)

2.5, 1.8, 1.2

Weight (kg.)

26.4, 18.0, 11.9

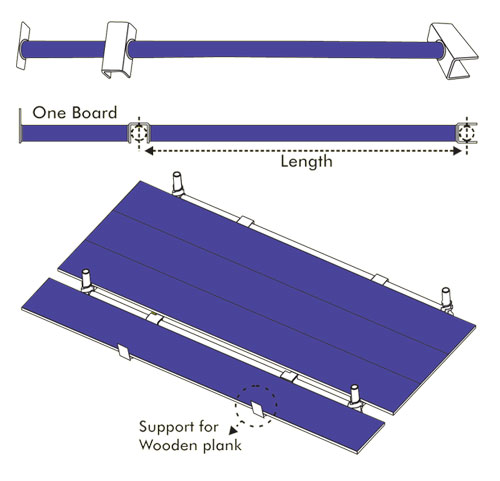

Using to provide skeletal support for plywood decking

Length (m)

1.7, 1.5, 1. 2, 0.9

Weight (kg.)

9.1, 8.1, 6.5, 5.0

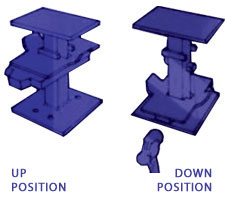

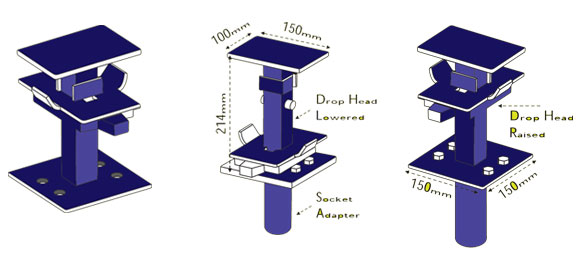

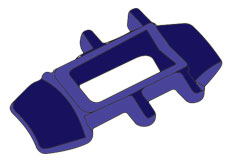

The quick action drophead supplied along with nuts and bolts is designed to fit on standard props or adaptors for cuplock scaffolding.

Maximum axial load:

40kN

It is used in combination with Universal jack for slab support with aluminum & timber beams

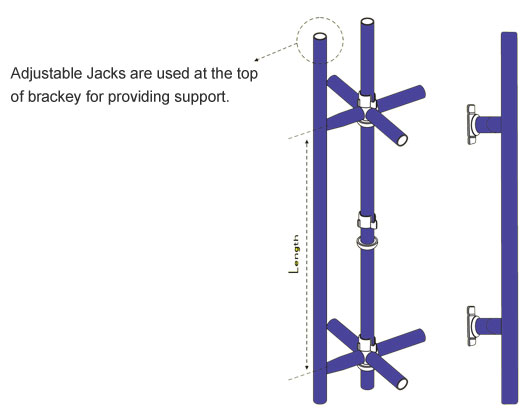

This is used at the top of scaffold structure with an adjustment option of raising or lowering the structure

It is made from high grade steel with rolled thread on it & forged jack nut to help the adjustments

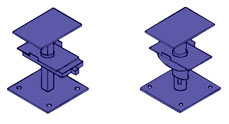

Socket Type / Pin Type Base Plate.

This is used to hold the tubes in position & the plate distributes the load.

It is made of high-grade steel with rolled threads & the U is used to hold the Timber or Aluminum beams in position for the slab support

1. U head

150 x 170 x 5.8

150 x 200 x 5.8

2. Connecting Pin

3. Bolts & nuts

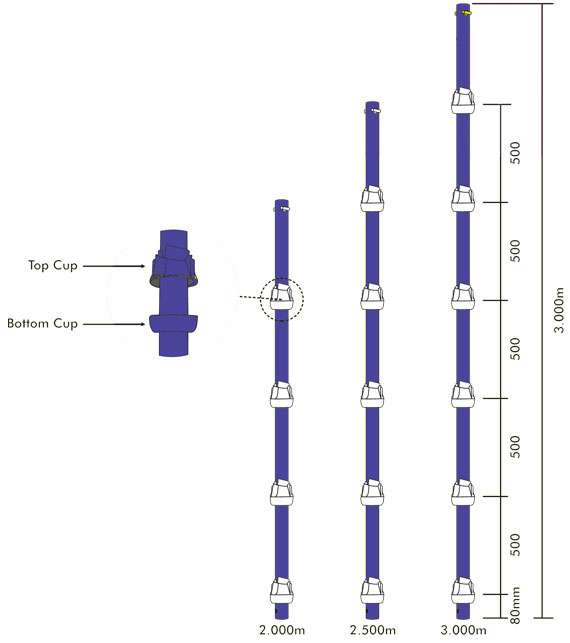

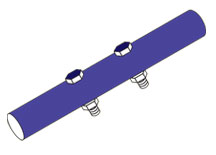

Made from 48.3mm diameter x 3.2mm thick high grade steel tube, Lock system Standards (Vertical) are formed by two cups a fixed bottom cup which is welded to the Standard (Vertical) at pre-located intervals i.e. 500mm and a sliding top cup. The forged blade ends of the Ledger (Horizontal) are located into the bottom cup. The top cup is moved down and rotated to secure the components in place and tightened by a hammer blow to give a positive and rigid connection.

|

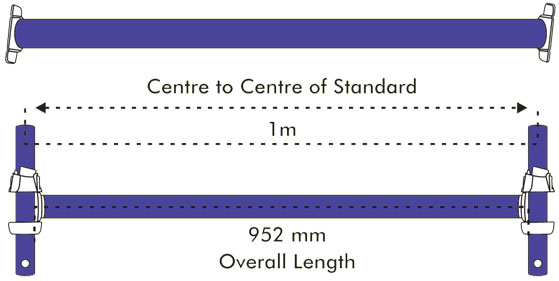

Made from 48.3mm diameter high grade steel tube with forged steel blade ends, which locate into the bottom cups of the Standard (Vertical) and are locked in place by the corresponding top cups.

| Code | Length (m) | Painted | Self Finish | Hot Dipped |

| PL-1311-06 | 0.600 | 2.370 | 2.300 | 2.530 |

| PL-1311-09 | 0.900 | 3.404 | 3.300 | 3.630 |

| PL-1311-10 | 1.000 | 3.750 | 3.650 | 4.000 |

| PL-1311-12 | 1.200 | 4.430 | 4.300 | 4.730 |

| PL-1311-13 | 1.300 | 4.850 | 4.700 | 5.170 |

| PL-1311-16 | 1.600 | 5.870 | 5.700 | 6.270 |

| PL-1311-18 | 1.800 | 6.600 | 6.400 | 7.040 |

| PL-1311-25 | 2.500 | 8.900 | 8.650 | 9.500 |

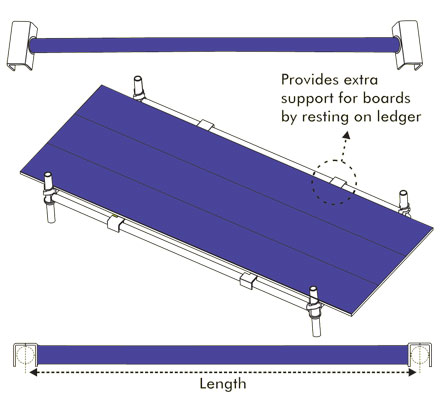

Made from 48.3mm diameter high grade steel tube. They rest upon the ledgers at right angles to reduce the span and provide extra support for boards. One end is provided with an integral locking device to prevent any movement along with the ledgers during use.

| Code | Length (m) | Painted | Self Finish | Hot Dipped |

| PL-1313-05 | 0.565 | 4.000 | 3.900 | 4.290 |

| PL-1313-08 | 0.795 | 4.850 | 4.700 | 5.150 |

| PL-1313-08 | 1.200 | 6.280 | 6.100 | 6.700 |

| PL-1313-13 | 1.300 | 6.590 | 6.400 | 7.000 |

| PL-1313-18 | 1.800 | 8.340 | 8.100 | 8.900 |

| PL-1313-25 | 2.500 | 10.900 | 10.600 | 11.650 |

Made from 48.3mm diameter high grade steel tube. Drop into place over the ledgers and are secured with a locking device to prevent movement. Act as conventional transoms but extend beyond the inside ledger to provide intermediate support to one or two inside boards.

| Code | Length (m) | One Board | Two Board |

| PL-1650 | 0.500 | 2.400 | 2.465 |

| PL-1651 | 1.000 | 3.404 | 3.493 |

| PL-1652 | 1.500 | 3.750 | 3.848 |

| PL-1653 | 2.000 | 4.400 | 4.514 |

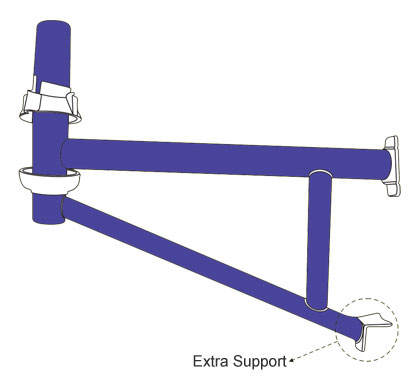

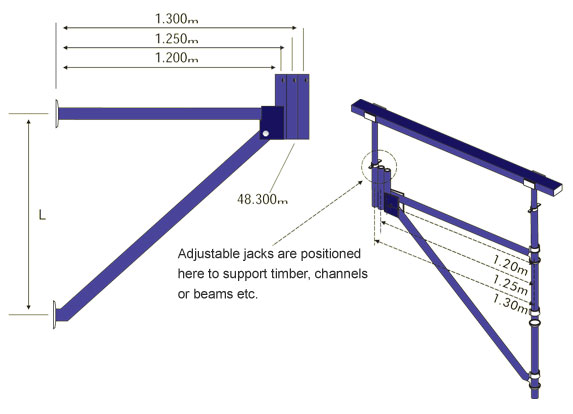

Beam Brackets are made from 48.3mm diameter high grade steel tube and are used to provide support to beam formwork from also support standards with provision for accepting jacks or fork heads. It has a safe load carrying capacity of 1500 kgs. The beam bracket distributes the load throughout the surrounding cuplock system structure, thus reducing excessive strain on all components

| Code | Length (m) | Weight (kg) |

| PL-1658 | 1.000 | 4.700 |

| PL-1659 | 1.500 | 6.400 |

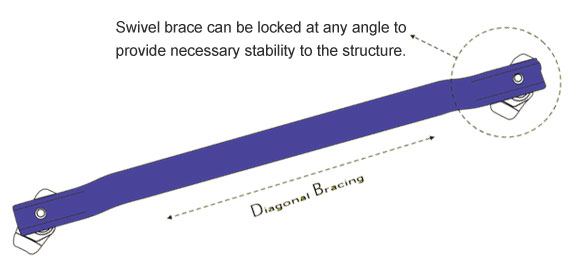

Diagonal braces are made from 48.3mm diameter high grade steel tube with a swivel blade at each end. They are placed diagonally from ledger to ledger, next to the standards to which they are fitted.

| Code | Length (m) | Weight (kg) |

| PL-1654 | 2.5 x 20 | 11.500 |

| PL-1655 | 2.50 x 15 | 10.700 |

| PL-1656 | 1.80 x 2.0 | 9.800 |

| PL-1657 | 1.80 x 1.5 | 8.700 |

Hop-up Brackets are made from 48.3mm diameter high grade steel tube and are used to increase the width of working platform used in conjuction with transoms / intermediate transoms or inside- board transoms. Thay incorporate a cup joint at the outside end to allow the fitting of an inside ledger which links the hop-up brackets and supports transoms / intermediate transoms.

| Code | Length (m) | Weight (kg) |

| PL-1660 | 1 Board | 1.800 |

| PL-1661 | 2 Boards | 6.300 |

| PL-1662 | 3 Boards | 7.700 |

Hop-up Brackets are made from 48.3mm diameter high grade steel tube and are used to increase the width of working platform used in conjuction with transoms / intermediate transoms or inside-board transoms. Thay incorporate a cup joint at the outside end to allow the fitting of an inside ledger which links the hop-up brackets and supports transoms / intermediate transoms.

|

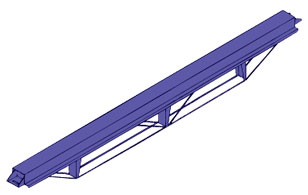

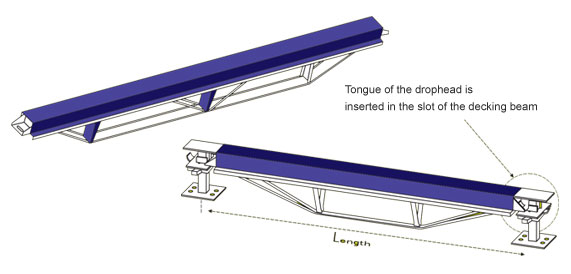

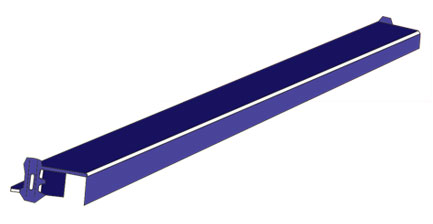

Decking Beams are designed with 100mm top flange which gives more support to the plywood. Tongue of the drop heads are inserted in the slots of the decking beam at both ends.

| Code | Length (m) | Weight (kg) |

| PL-1628 | 1.200 | 13.400 |

| PL-1626 | 1.800 | 20.000 |

| PL-1643 | 2.500 | 28.000 |

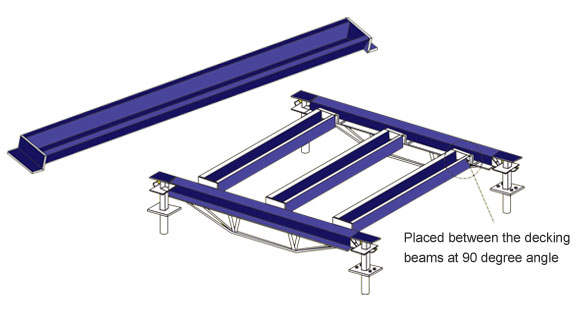

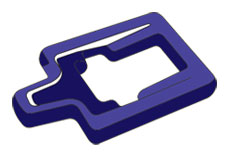

They are manufactured from 2mm thick top quality steel sheet and are designed to be used with the decking beams and are spaced out at predetermined centres to support the plywood.

| Code | Length (m) | Weight (kg) |

| PL-1644 | 0.900 | 5.230 |

| PL-1645 | 1.200 | 6.700 |

| PL-1646 | 1.500 | 8.700 |

| PL-1647 | 1.700 | 9.800 |

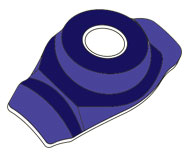

The quick action drophead is designed to fit on standard props or adaptors for cuplock scaffolding. The primary head remains in contact with the concrete while the secondary head and its supporting wedge arte released by a single hammewr blow. The deophead has a load carrying capacity of 40kN.

| Code | For Tube OD (mm) | Weight (kg) |

| PL-1625 | 48.2 | 5.000 |

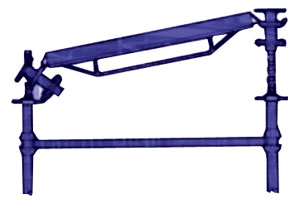

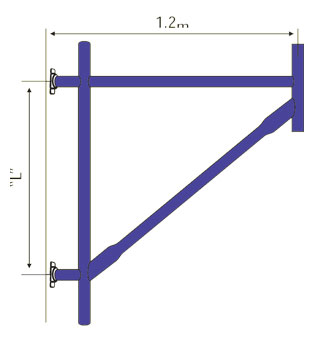

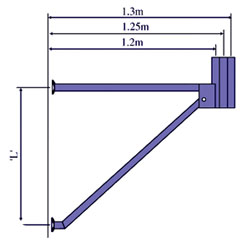

This frame has ledger blades to be fitted into Cuplock standards at one end and with provision for accepting jacks in three positions at the other end at 1.2m, 1.25m and 1.3m from centerline of the standard.

| Code | Length (m) | Weight (kg) |

| PL-2612 | 1.000 | 14.500 |

| PL-2613 | 1.500 | 16.500 |

| Code | Length (m) | Weight (kg) |

| PL-2631 | 1.000 | – |

| PL-2632 | 1.500 | – |

Return Transom is used at the end of a scaffold run where it meets another scaffold running at right angles to it. The U-shaped return section of the transom hooks over the ledger of the adjacent scaffold, closing off the gap between the two scaffold.

| Code | Length (m) | Weight (kg) |

| PL-1666 | – | 8.500 |

Omega Transoms are manufactured from press bent section with flange type extensions on both sides provides a strong support for working platform with Cuplock steel battens.

| Code | Length (m) | Weight (kg) |

| PL-1667-A | 1.300 | 7.200 |

| PL-1667-B | 1.800 | 10.000 |

| PL-1667-C | 2.500 | 24.800 |

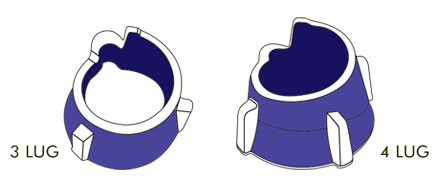

The captive mobile cups are made out of Malleable cast iron to ensure rough site handling.

| Code | Lug | For Tube OD (mm) | Weight (kg) |

| PL-1390-113C | 3 | 60.0 | 0.440 |

| PL-1390-114C | 4 | 60.0 | 0.440 |

| PL-1390-113F | 3 | 48.3 | 0.430 |

| PL-1390-114F | 4 | 48.3 | 0.430 |

Bottom cups are pressed from high quality steel and are welded on vertical.

| Code | Sheet Thick.(mm) | For Tube OD (mm) | Weight (kg) |

| PL-1390-140 | 4.0 | 48.3 | 0.200 |

| PL-1390-145 | 4.5 | 48.3 | 0.220 |

| PL-1390-160 | 4.0 | 60.0 | 0.215 |

| PL-1390-165 | 4.5 | 60.0 | 0.240 |

| Code | For Tube OD (mm) | Weight (kg) |

| PL-1390-122-48C | 48.3 | 0.222 |

| PL-1390-122-48P | 48.3 | 0.217 |

| PL-1390-122-60C | 60.0 | 0.265 |

| PL-1390-122-60P | 60.0 | 0.260 |

SF-1390-121

Tube OD : 48.3mm

Weight : 0.365 kg.

SF-1315

Tube OD : 48.3mm

Weight : 1.200 kg.

SF-1390-123

Tube OD : 48.3mm

Weight : 0.276 kg.

SF-1668

Weight : 1.500 kg.

SF-1390-16

Tube OD : 48.3mm

Weight : 1.100 kg.

SF-1390-15

Tube OD : 38mm

Weight : 0.710 kg.

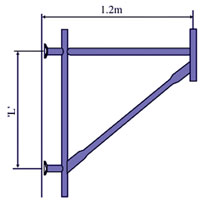

Available Sizes:

L : 1.5M – L : 1.0M

Available Sizes:

L : 1.5M – L : 1.0M

Available Sizes:

L : 1.5M – L : 1.0M

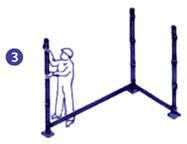

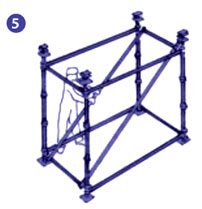

Space out socket bases and stand in jacks if required (plain shank at top).

Assemble a standard on a jack and two ledgers at right angles in a lower cup of this standard. Drop the upper cup of the joint over the two blade ends. Do not tighten.

Take a second standard and assemble on another jack, fixing the blade end of the previously assembled ledger into the cup of this standard. Repeat for the third standard to complete a right angled comer.

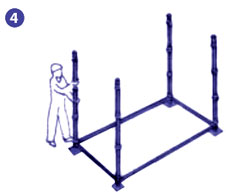

Add the fourth standard and two more ledgers in a similar manner to complete the assembly of 4 standards and 4 ledgers.

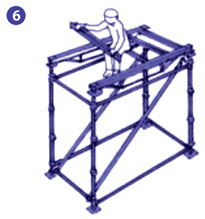

Add the upper layer of four ledgers and two braces and assemble the upper jacks and drop head assembles on the top of the completed supporting grid.

Finally, add the primary beams and infills in the completed support structures and as grids are completed, tighten all joints.

Adjacent supporting grids may be added in a similar way and primary beams and infills added until the required area is completed.

Dismantling Procedure

Dismantling follows the same procedure whether the techniques of ‘early striking’ are followed or not.

The advantages of early striking is that the primary beams and infills may be removed while the concrete soffit remainssupported and completely undisturbed during it’s curing period. The primary beams and infills may therefore be re-used this time, thus gaining further concrete production with only and additional set of supporting components.

Primary beams and infills may be removed by striking the drophead wedge. While the primary head of the drophead remains in contact with the concrete, the striking of the wedge allows the beams to drop about 115mm only giving sufficient clearance for the removal of the infills.

Whether the advantages of ‘early striking’ are taken or not, complete safety in dismanting operations is ensured as primary beams and infills cannot fall to the ground but after striking, must be removed manually.

To assemble Decking on Cuplock Scaffolding remove the drop head assembly from the jack at one end and connect it to the beam. The completed beam with its drop head can now be raised and dropped over the jack.”